A case study of Ethic Co.,Ltd. which has installed the JV330-130, was published in the sign industry magazine “Kanbankeiei” , Vol. 33 (June 2024 issue).

The following is the published article in its original form.

JV330's superior usability goes beyond high image quality and high speed.

Trust cultivated through pursuit of a field-oriented approach and after-sales follow-up

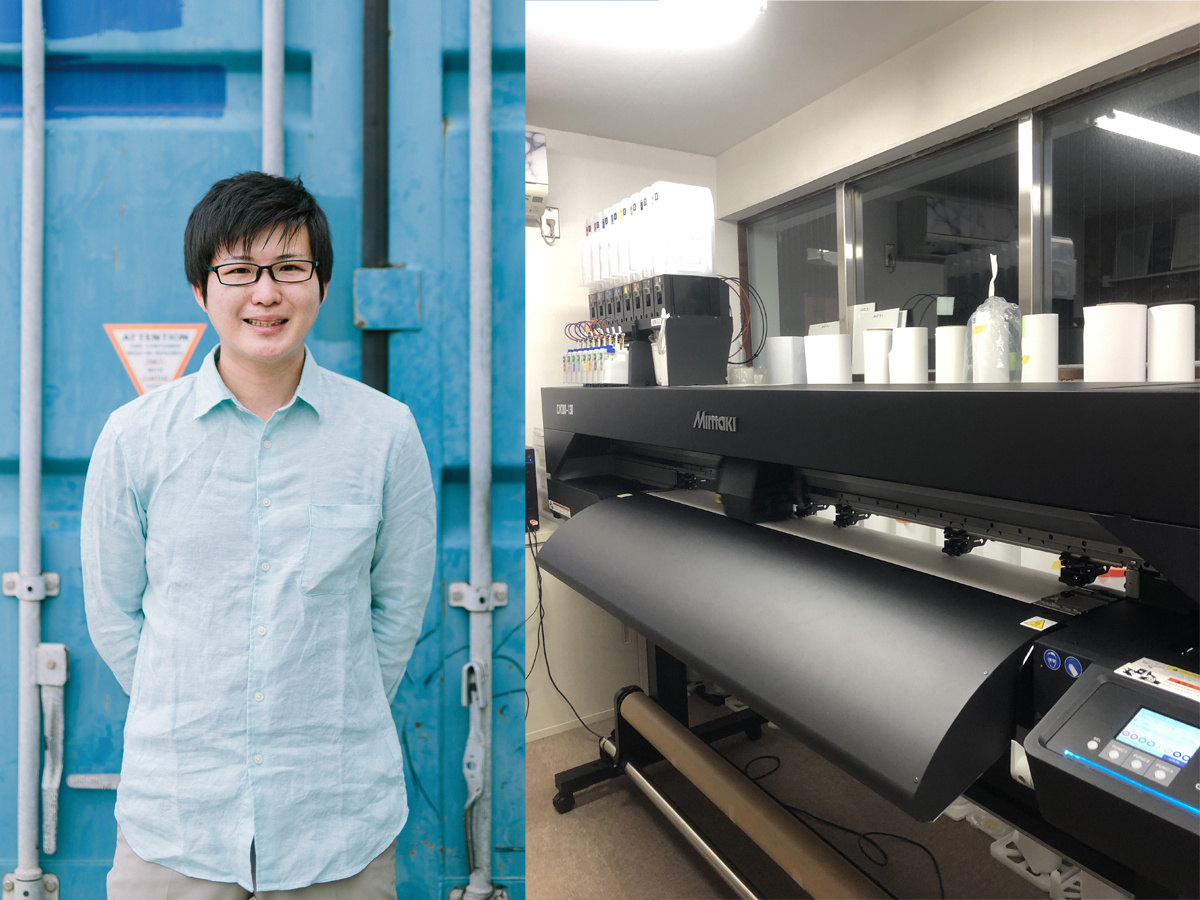

Based in Kawaguchi-shi, Saitama, Ethic is a sign manufacturer and installer. With the attention to detail and the flexibility of a small, elite team of three employees, the company has earned the trust of advertising agencies and local businesses, its main clients, for about 30 years since its establishment in 1995. In May 2023, the company has introduced Mimaki Engineering's JV330-130, a flagship model of low-solvent machine. In addition, almost all of the company's main machines, including the UJF-6042MkII e flatbed UV machine and the CG-130FXII cutting plotter, are made by the company. Where does this trust come from? In this interview with art director Naomi Fujii, we will find out.

Naomi Fujii, Art Director

First, how did you come to know about JV330-130?

It all started when we were considering replacing a machine from another company and it was recommended to us. With the previous machine, we were having trouble with stable color reproduction of solid filling. When outputting large signboards, the joints were noticeable, and we had experienced complaints. In such a situation, the color reproduction and color quality of this machine was overwhelming compared to other companies' machines. The initial cost was not cheap because it is a flagship model, but we took the plunge and installed it because Mimaki is dependable.

― What were the factors that made you so sure?

Actually, there was a time when we used Mimaki's eco-solvent machine. Since then, we had no complaints about the image quality and speed, so we had high expectations that the successor machine, the JV330-130, would be able to produce even cleaner and faster output.

In addition, we also had other cutting plotters and desktop UV machines made by Mimaki, all of which were easy to use, and even if we had a problem, they would always visit us on the same day or provide remote support. We had no worries about the introduction of the system because of the relationship we had built up with the sales staff.

― What are your impressions after actually putting it into operation?

We are amazed at how much better the results exceeded our expectations. Both image quality and speed are perfect, and work efficiency has increased 1.2 times compared to the previous system while improving quality. I have the impression that colors with strong shading, such as solid red, come out particularly beautifully. Of course, there is no problem at all with light feminine colors. The wide color gamut and stability of the machine make it ideal for a company like ours, which specializes in sign production.

The 330 series' strength lies in its ability to reproduce gentle, pale colors as well as solid filling such as red, which is often used for signage.

― Please let us know if there are any other functions that you make effective use of.

From a user's point of view, the "media changer," which makes it easy to change rolls by simply turning the handle, has been very helpful. Since we work with a small number of people, there are many cases in which I have to change the rolls by myself, which is a hard task for me since I do not have strong arms. I am also very satisfied with the new 2L ink capacity, which reduces the time and effort required to change the ink.

If I have to make a request, I would be even more happier if the "XY Slitter" function could be made more versatile. We are also in the business of using media scraps left over from output to make products such as plate signage, which we sell on our e-commerce site while reducing waste. If the "XY Slitter" could be made more compatible with all kinds of materials, its compatibility would increase, but to be honest, we have not yet fully utilized it. We would like to explore better ways to use it.

― Is there any equipment you are planning to introduce in the future?

I have heard about PICT, a cloud-based tool that allows us to visualize the status of large format printers using a PC or smartphone, and I have a strong interest in it. It is very attractive to be able to remotely know the ink usage, inventory management, and operating status of each machine. As I believe it will lead to further improvement of the machine's efficiency, I would like to consider full-scale introduction.

JV330-130

User profile

- NameEthic Co.,Ltd.

- IndustrySignboard production and installation, sticker production and sales, digital signage design, production and installation

- Address2-23-8 Higashi-ryoke, Kawaguchi-shi, Saitama, Japan

- Phone number+81-48-229-2973

- URLhttps://ethic.tokyo/