Mimaki doming kit

Doming is one of coating and decorating methods and adds 3D effect on to 2D print surface. Special liquid polyurethane resin covers the print surface and creates dome shaped finish by surface tension.

Many tools are required for doming.

Prepare liquid doming resin

Mix same amount of liquid resin and curing agent.

Since both of liquids have same specific gravity, a digital scale is used.

25g each liquid is mixed together and 50g liquid doming resin is prepared.

Vacuum mixing

Pour the liquid in to a cup and cover it, then attach to a vacuum mixer.

Mix the resin for 6 minutes in a vacuum.

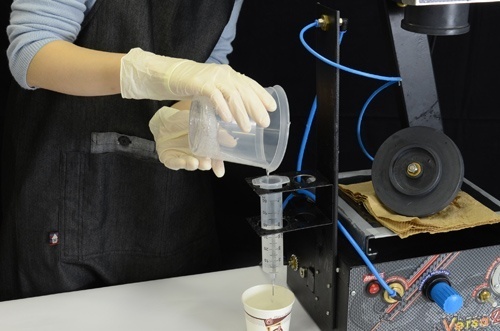

Fill a syringe with the resin liquid

Stop the mixer after 6 minutes and unlock for removing the cup.

Pour the liquid carefully in to the syringe. Place a paper cup under the syringe to prevent leaking.

Cap the syringe tightly.

Start doming!

Drop the liquid from the syringe.

The resin is ejected by air pressure from a compressor.

Thanks to the high-viscosity of the liquid resin, the resin is applied easily.

Apply a large amount of resin on two places of the smartphone case surface. The dropped resin is spread and stopped at the edge by itself.

Make a final adjustment manually

Cover the surface with the resin with a small brush or a rubber spatula.

If air bubbles are found, warm the resin to remove them with a gas torch.

Place the case in a dry chamber and leave it overnight.

Place the case in a dry chamber and keep it horizontally.

After one hour, check the surface of case whether air bubbles are arisen.

Finished product

This is the finished product.

Glossy domed surface is very attractive and adds value to printing.

Finish comparison

Note

- The appearance of the finished product may vary depending on conditions and environment such as room temperature. Please test before starting production.

- Content in this website is subject to change without notice.