From Life-Size Panels to Seals and Stickers: Size-Flexible Applications Expand In-House Production and Boost Repeat Orders

REC corp. (Nagoya-shi, Aichi), which manufactures and sells recycled toner for laser printers, started a creating business as a new project in 2015. They are trying to make a variety of things such as signs, T-shirt prints and original goods made of acrylic material.

In November 2024, they introduced Mimaki's flatbed cutting plotter "CFX" to strengthen its manufacturing capacity. This expanded the scope of business and succeeded in acquiring new customers and repeat customers.

We talked with the company about the background of the introduction of CFX and specific operation methods.

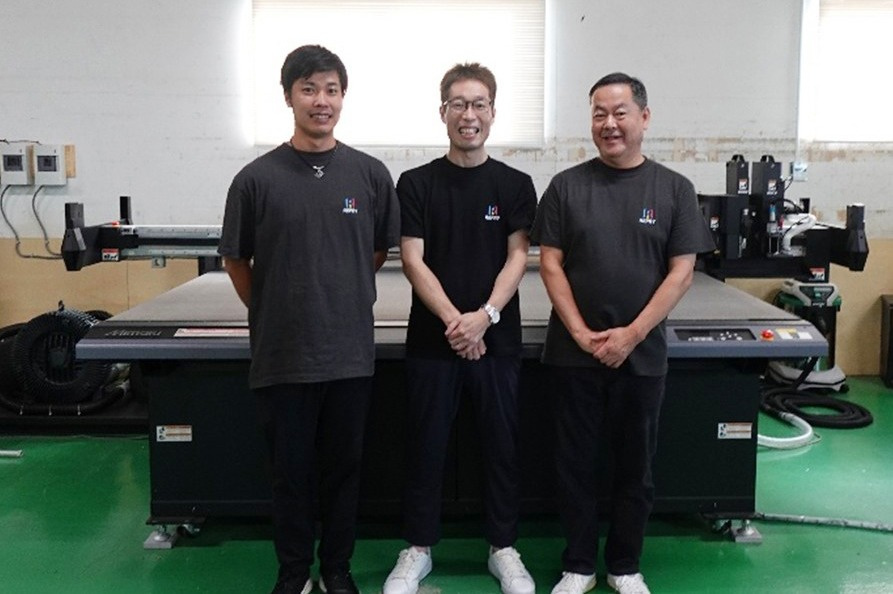

From left to right: Operator Satoshi Takeda, Center Director Akimitsu Sugiyama, and Operator Tadashi Mutsushika

A Shift Toward Creating Businesses as Paper Printing Declines Due to COVID-19

Since our founding, we have been engaged in the manufacture and sale of recycled toner for laser printers. In recent years, paperless has spread in the aftermath of remote work due to the COVID-19. A decrease in paper printing will also affect sales of printers and recycled toner. As a new project, we introduced a laser processing machine in 2015 and started manufacturing things.

In order to increase in-house production, we also introduced flatbed UV printers, DTF printers, 3D printers, and metal sheet bending machines. At present, we make various original goods such as signboards, panels, posters, event T-shirts and key holders.

Cut a laser-resistant aluminum composite plate with a cutting plotter

Among the products we handle, there is a life-size panel using a hard aluminum composite plate. If we cut this along the shape of the panel with a laser machine, the cross section will melt due to the heat of the laser and it will not be finished the way we imagine. In addition, when cutting thin sheet film, the cross-section was scorched and the quality was affected.

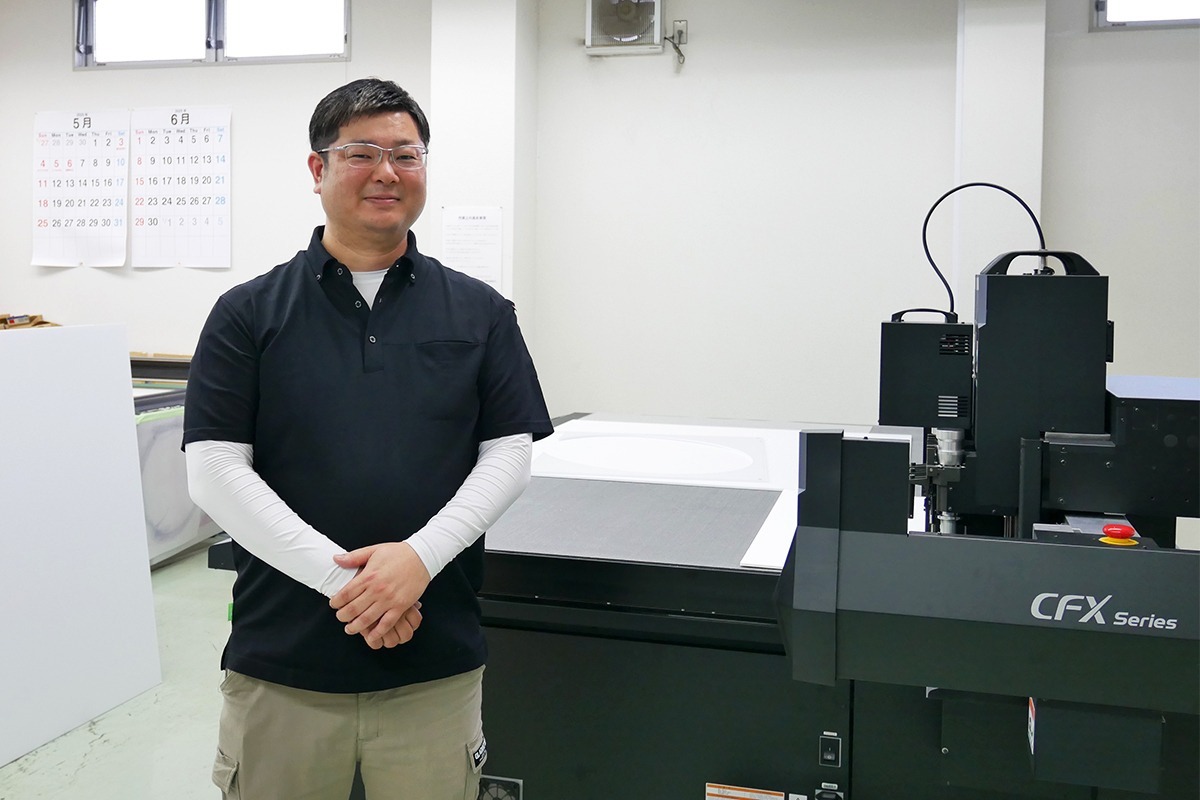

In November 2024, we introduced Mimaki's cutting plotter "CFX-2513" to solve the problems associated with laser cutting.

As I have used an inkjet printer made by Mimaki for a long time, I had trust. Another advantage of using Mimaki machines in all factory facilities is that software compatibility and maintenance can be performed smoothly, and the affordable price range also supported the introduction of the system.

Sample of aluminum composite plate cut with CFX-2513

No Burn Marks on Cut Edges and High Positioning Accuracy Deliver Strong Satisfaction

When I actually touched the CFX, I was amazed at how easy it was to use. Originally, our company is a manufacturer of recycled toner, and although I am a beginner in manufacturing, I can operate it without difficulty. The software attached as standard was easy to use, and even staff with little experience in graphic software could quickly learn it.

The cutting accuracy is high, and the trim mark reading function does not cause positional deviation when cutting. I am also satisfied with the quality of the life-size panels. The scorching of the cut section that had occurred with laser machine has been eliminated, and we can now propose it to our clients with more confidence than ever before.

Currently, CFX is used in a wide range of applications, including life-size panels, various panels with complex shapes, thin sheet films, thick cardboard, and resin plates made of vinyl chloride and PET materials.

In addition, CFX also cuts fine work such as cut letters on signboards, small lots of seals and stickers, and product mount to be enclosed in the package of original goods. The mount of the product is small, but it will finish beautifully without deviation of the cut position.

In the past, it took a long time to deliver the paper because we had to outsource the production of the mount to a printer. Now, however, we are able to manufacture the entire mount and respond quickly to urgent requests for work.

Life-size panels made with CFX-2513

Expanded Scope of Work Drives Growth in Repeat Orders and Inquiries from Industry Peers

Until now, we had no choice but to decline projects that we could not process ourselves. However, with the introduction of CFX, the process from printing to cutting can be done consistently. The repertoire of products that can be produced in-house has increased, and the range of work has expanded.

We sometimes receive a request for cutting from a company in the same industry, saying, "I want you to make a cut letter of aluminum composite plate."

Additional orders from repeat customers also increased. Recently, we received an order for an original mudguard to be installed on trucks. After printing with Mimaki flatbed UV inkjet printer "JFX200-2513 EX", it is cut and finished with CFX.

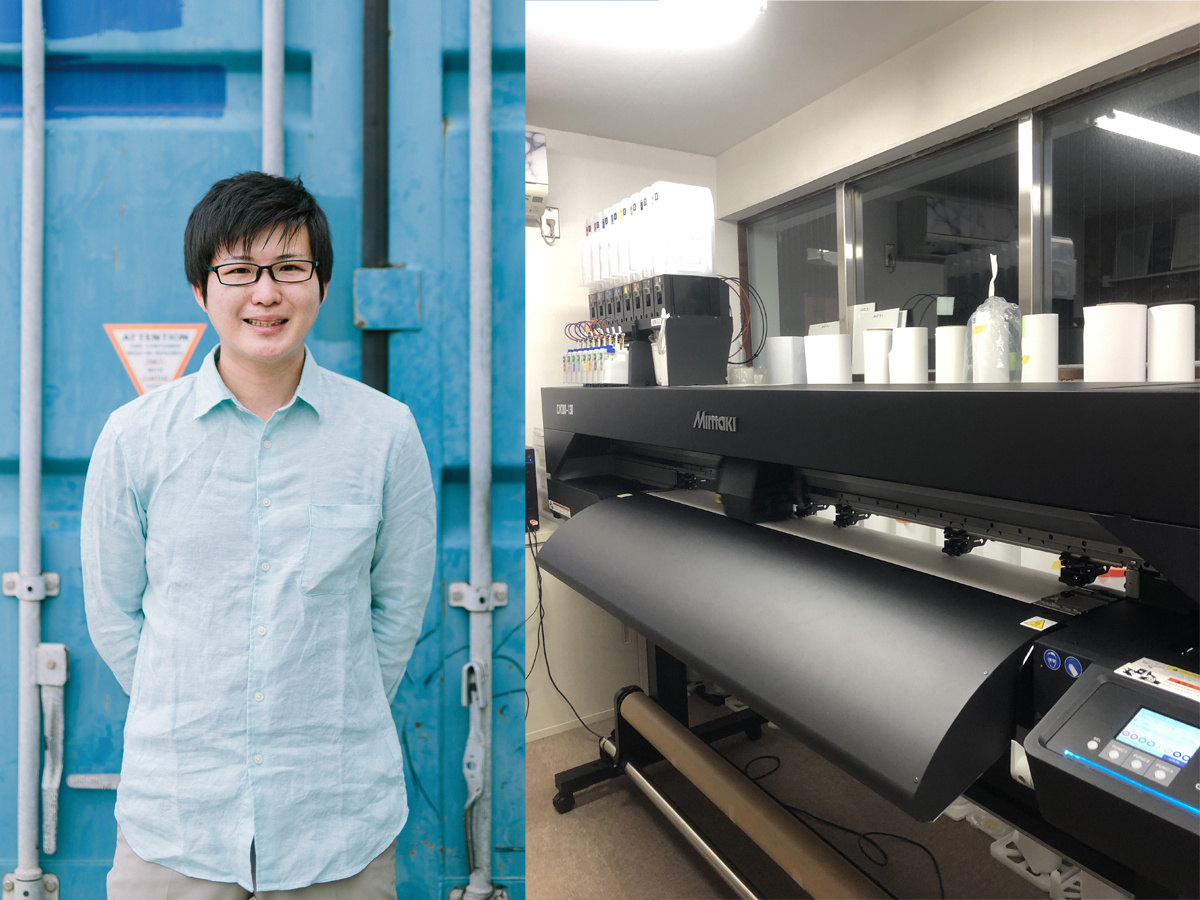

JFX200-2513 EX

In the future, we would like to increase orders for life-size panels, which is our strength. The current needs are mostly for event banners for club-type restaurants, but we have also worked on a life-size panel at the request of a popular YouTuber. I would like to develop sales channels based on event-related products to attract new customers. In the future, we also plan to produce and sell original goods under our own brand. I would like to make more use of CFX in the production of those goods.

A bumpy 2.5D print with a Picasso design

User profile

- NameREC Corp.

- IndustryManufacture and sale of recycled toner for laser printers; production of signboards, signs, and original merchandise

- Address1-4-14 Minami-Horikoshi, Nishi-ku, Nagoya-shi, Aichi, Japan

- Phone number+81-52-528-3222

- URLhttps://www.rectoner.net/